end mill coating types

TiN is the most common wear and abrasion-resistant hard coating. Request a Test Now.

Destiny Tool Products Destiny Tool

Compared to square end.

. They are single-ended tools that makes corner radii and a milled shoulders bottom. Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. 2 Ball Nose Short End Mill.

TiAlN coating is an extremely popular option for use with carbide end mills today and for good reason. Take the Guesswork Out of Optimizing Your Milling Applications. Ad Only Available at MSC.

Consumers businesses alike trust in our innovative finishes to protect what matters most. Boost Productivity and Reduce Costs in Minutes With Our New Service. Read customer reviews find best sellers.

Up to 16 cash back For fast cuts and the greatest rigidity use shorter end mills with larger diameters. Some coatings are nothing short of magic when it comes to their performance impact. Titanium Nitride TiN This is the most popular.

TiN - Titanium Nitride - basic general-purpose wear-resistant coating. This coating works great while. These are corner radius end mill cutters.

Single End and Double End Cobalt Long Metric Miniature Roughing. BULL-NOSE END MILL. Advances in end mill coatings are being made however with coatings such as Amorphous Diamond and nanocomposite PVD coatings beginning to be seen at high-end shops as of.

Browse discover thousands of brands. Arc Evaporation ARC High-power impulse magnetron sputtering HiPIMS. Use cobalt PMPlus and.

4 Flute Square Long End Mill. End Mill Coatings. G-Wizard calculators default surface speed is 20 higher for a TiAlN coated end mill versus an.

The use of coatings will increase the surface hardness of the tool. This will allow for greater tool life and faster cutting speed. At a basic level the mix of.

There are two end mill. Down-cut end mills do the opposite they leave a smooth top. Variable helix end mills reduce chatter and vibration.

Many of our end mills are offered in a variety of standard coatings that are best suited for the intended purpose of the end mill application. Thin better edge toughness smoother. Ad Only Available at MSC.

Coating Type Code No. 4 Flute Square Short End Mill. 17 rows End Mills coating typesPVD CVD Basically there are 2 kinds of thin film deposition.

Common Coatings Titanium Nitride TiN General purpose PVD coating that increases hardness and has a high oxidation temperature. Corrosion is not a concern when steel is enclosed by building finishes coated with a contact. Contribute to sbmboyen development by creating an account on GitHub.

Choose the Right Helical Direction. Physical Vapor Deposition PVD. Titanium Aluminum Nitride TiAlN Coating.

Here is a full breakdown of different end mill coatings including industry abbreviation codes descriptions and ideal uses. Your end mills can be further coated with TiAlN Titanium aluminum nitride to increase cutting speed up to 25. It decreases friction increases.

Boost Productivity and Reduce Costs in Minutes With Our New Service. Take the Guesswork Out of Optimizing Your Milling Applications. Request a Test Now.

The good news is that steel corrosion can be addressed in a cost-efficient and effective manner. Ad Industry leading finishes in durability hardness plus scratch chemical resistance. Up-cut end mills eject chips towards the top of the workpiece leaving a cleanly cut bottom surface inside your material.

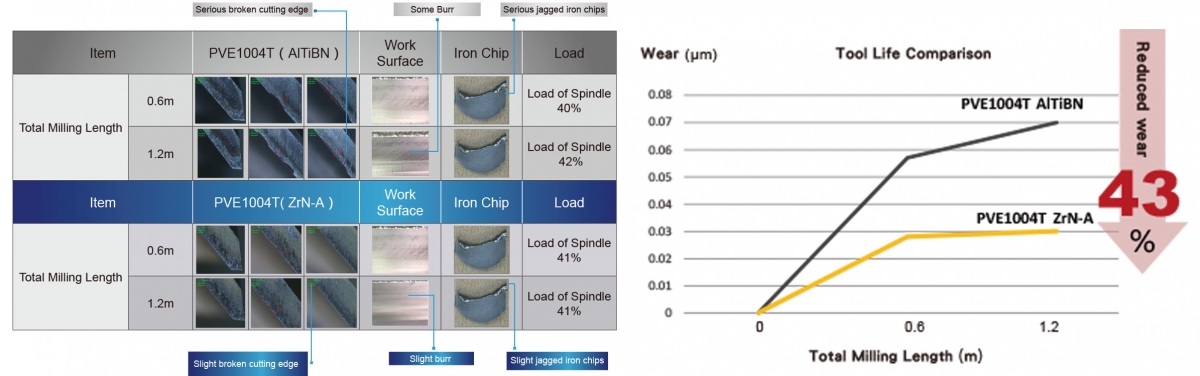

Coating Types And Features Technical Information Tools For Machine Processing Tools Misumi Vona Comprehensive Web Catalog For Misumi

What Is The Difference Between The Coating Of End Mill

How To Choose The Right Coating For You End Mill Speed Tiger

Tormach Explains Tool Coatings Youtube

3 Ways Tool Coatings Increase Tool Life In The Loupe

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

End Mill An Overview Sciencedirect Topics

End Mills The Essential Beginners Guide

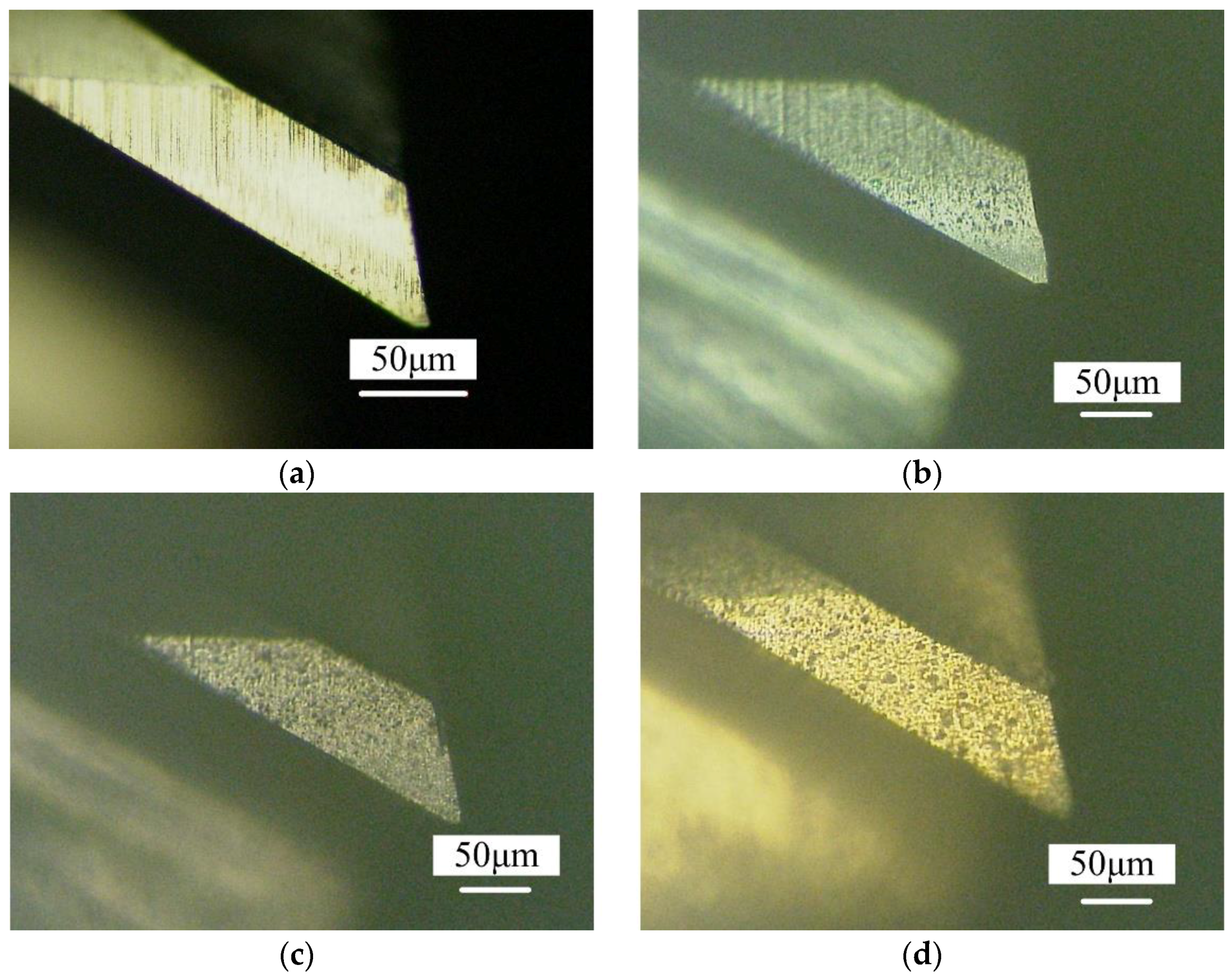

Micromachines Free Full Text Cutting Performance Of Different Coated Micro End Mills In Machining Of Ti 6al 4v Html

Cnccookbook 2018 End Mill Survey Winners Cnccookbook Be A Better Cnc Er

End Mill Coatings Destiny Tool

Coatings For Cutting Tools Staton

What Is The Difference Between The Coating Of End Mill

Applied Coating Systems On End Mills With D 12 Mm Download Scientific Diagram

Choosing The Right End Mill Coating For Each Application Tool Talk

Applied Coating Systems On End Mills With D 12 Mm Download Scientific Diagram

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool